Metal Parts Manufacturing Solutions and Supply

For all your steel parts needs, rely on A.I.M. We can take a complicated part and provide simple manufacturing solutions. If you bring us a component that has to be manufactured, our engineers will employ an efficient and cost-saving approach to help you achieve your production goal.

We have a diversified customer base, which means that we are familiar with the needs of a variety of industries. We have fabricated parts for the following:

What We Do

When you have serious production needs, you can always turn to our company. We can help you meet your manufacturing and production requirements through A.I.M.’s:

Machine Capabilities:

Laser Cutting Specialist:

A.I.M. utilizes the latest Eagle and Trumpf fiber lasers that achieve customer accuracy and desired finish quality.

A.I.M. currently has the following Eagle & Trumpf Fiber Lasers in production to meet your manufacturing needs.

- Eagle 30K Fiber Laser with Automation

- Trumpf 12K Fiber Laser with Automation

- Trumpf 10K Fiber Laser with Automation

- Trumpf 6K Fiber Laser

Machine Capabilities

- 10” Maximum Diameter

- 1/2” Minimum Diameter

- .38" Steel

- .38" Stainless

- .38" Aluminum

- Cut & Etch

Trumpf TruBend Robotic 7000 Cell

A.I.M. utilizes latest state of the art Trumpf press brakes with 260 ton capacity to bend & shape laser blanks with one of the fastest and most accurate Robotic press brakes so parts will be ready for your fabrication, production, and assembly needs

Machine Capabilities:

Press Brake Specialist:

A.I.M. utilizes the latest Trumpf Press Brakes to bend and shape laser blanks with one of the fastest and most accurate press brakes so parts will be ready for your fabrication, production, and assembly needs.

A.I.M. currently has the following Trumpf Press Brakes in production to meet your manufacturing needs.

The Press Brakes can bend parts up to 120” with 260 Ton Capacity.

- Trumpf 5230 Press Brake

- Trumpf 7050 Press Brake

- Trumpf 7036 Press Brake

- Trumpf 7000 Robotic Cell Press Brake

Machine Capabilities:

Milling Machine Specialist

A.I.M. utilizes the the Haas Machining Center to work with plastics, aluminum, steel, and soft metals

Machine Capabilities:

Finishing:

A.I.M. utilizes LISSMAC equipment for deburring, edge rounding, and finishing to provide a superior finish to lasered parts.

Machine Capabilities:

Mechanical Fasteners:

A.I.M. utilizes the Haeger 824 Window Touch 4e Pem machine with a 10-ton capacity. It is capable of installing multiple sizes and styles of pems for innovative applications to save time and money in the customer assembly process.

Welding Equipment:

A.I.M. utilizes Weldbot robotic welders & Lincoln Electric MIG and TIG Welding to cover your welding needs.

A.I.M. utilizes the Fronius TSP 500I CMT Water-cooled Welding System to provide superior welding finishes.

A.I.M. utilizes the Serra LightSAFE Laser Welding equipment to provide superior welding finishes.

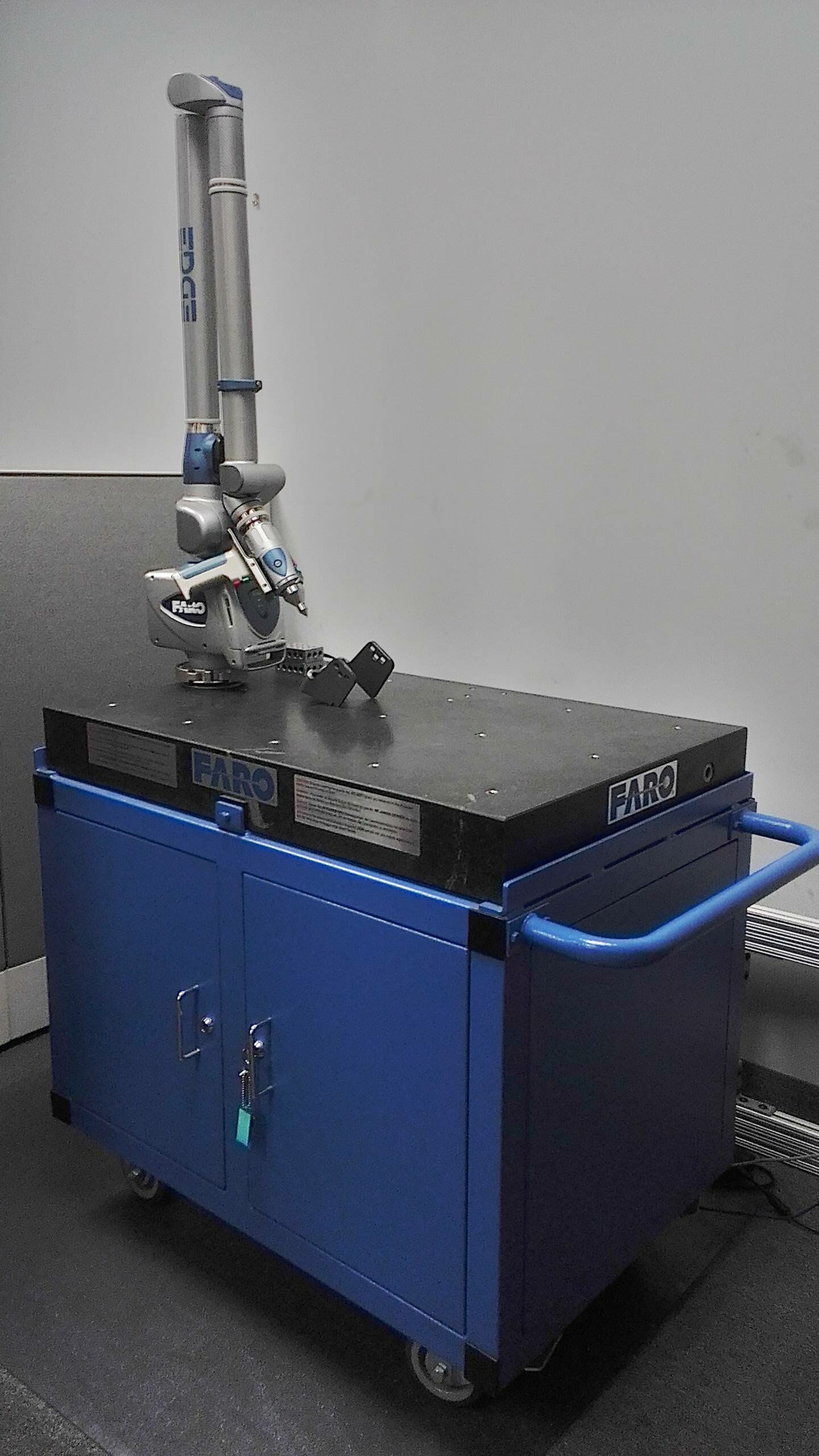

Quality Control Measuring Equipment:

A.I.M. utilizes the FARO Edge 7 Axis Laser Scanning Probe. This enables us to measure complicated parts down to .001".

Quality Control Measuring Equipment:

A.I.M. utilizes the Inspecvision Planar 2D which allows us to simply and quickly verify product quality by performing 2D inspection, CAD comparisons, and reverse engineering.